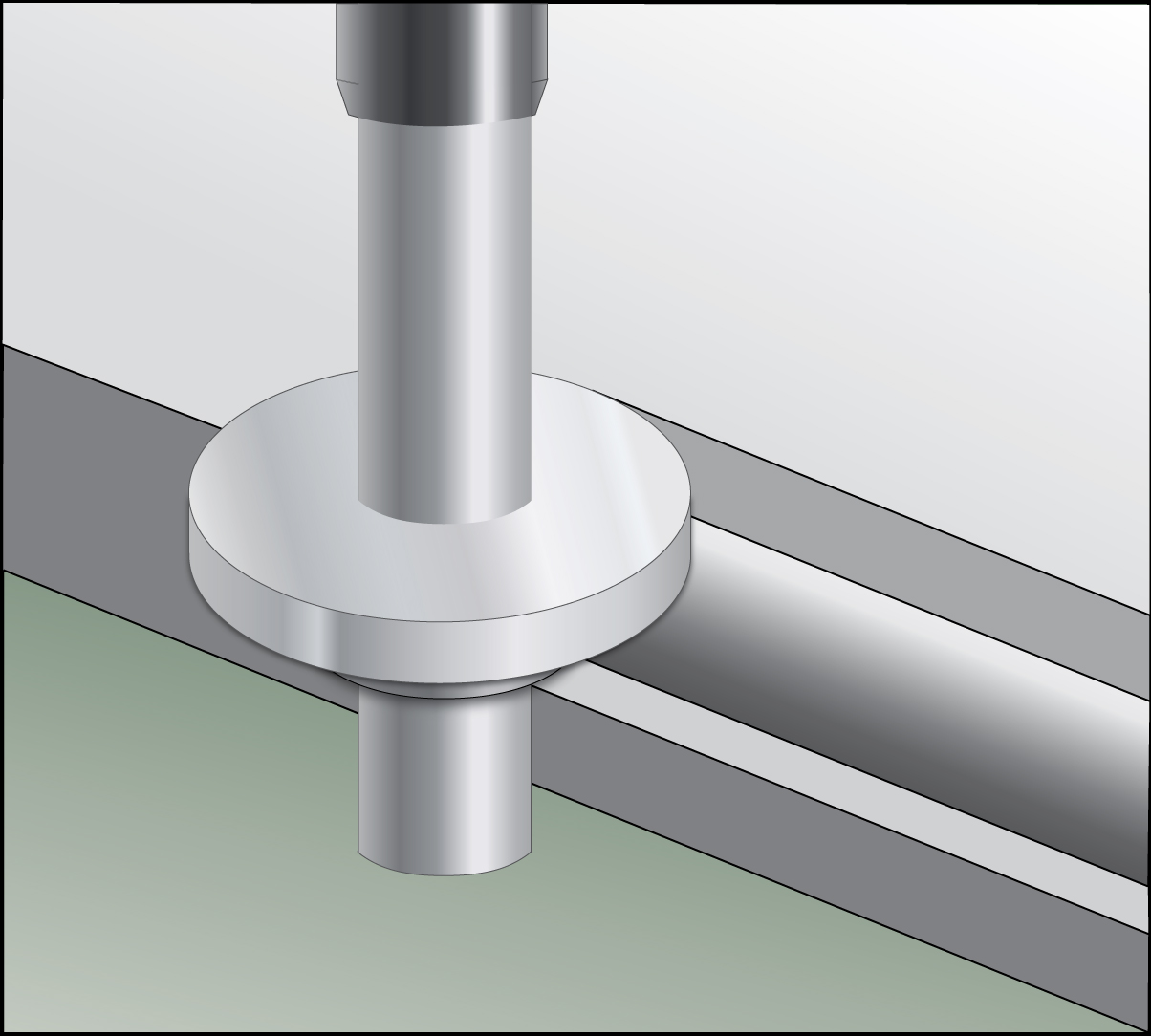

Routing

• Properly secure the product to minimize movement when routing.

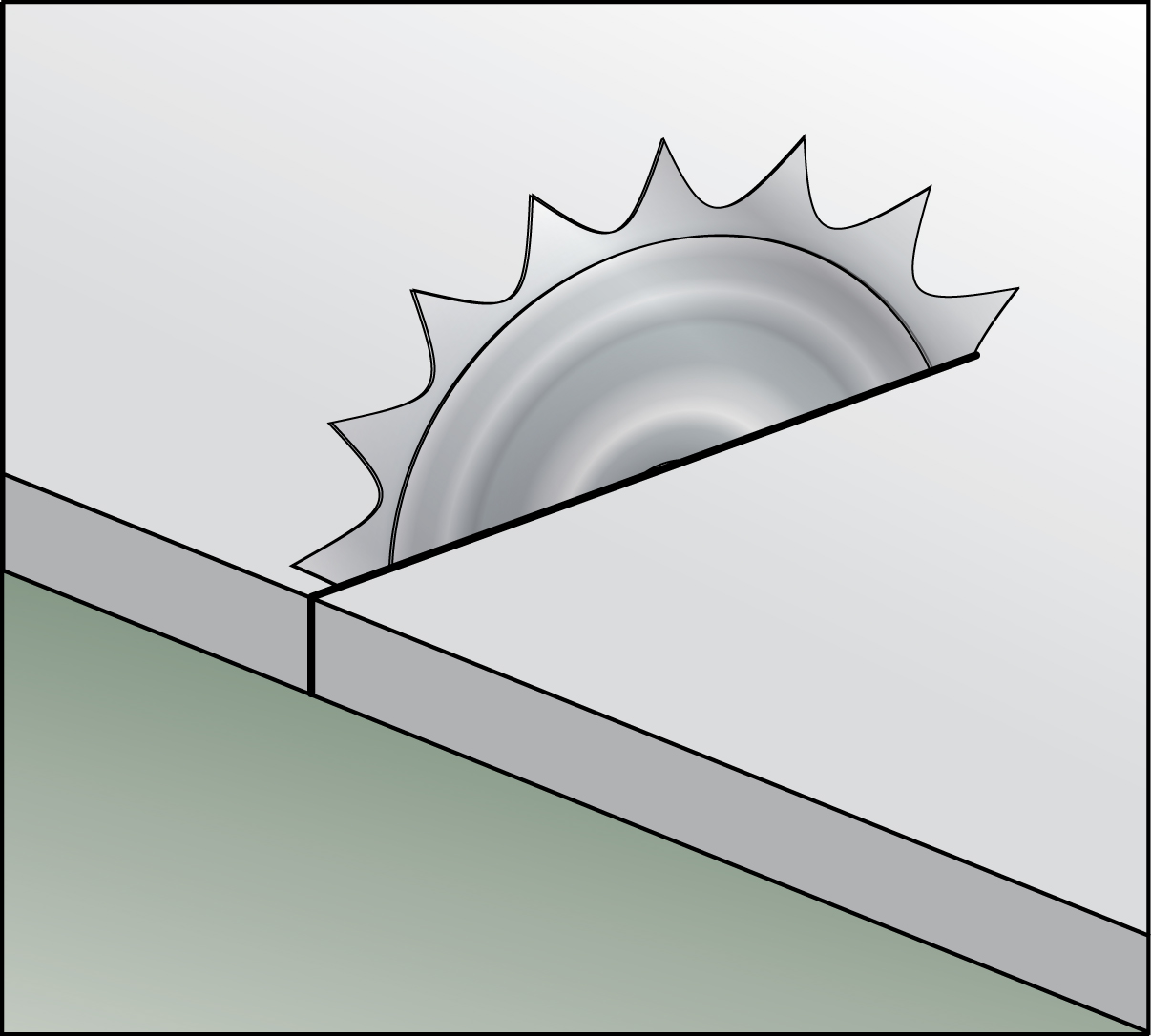

Cutting

• Avoid fine tooth blades.

• Properly secure trim to minimize movement when cutting.

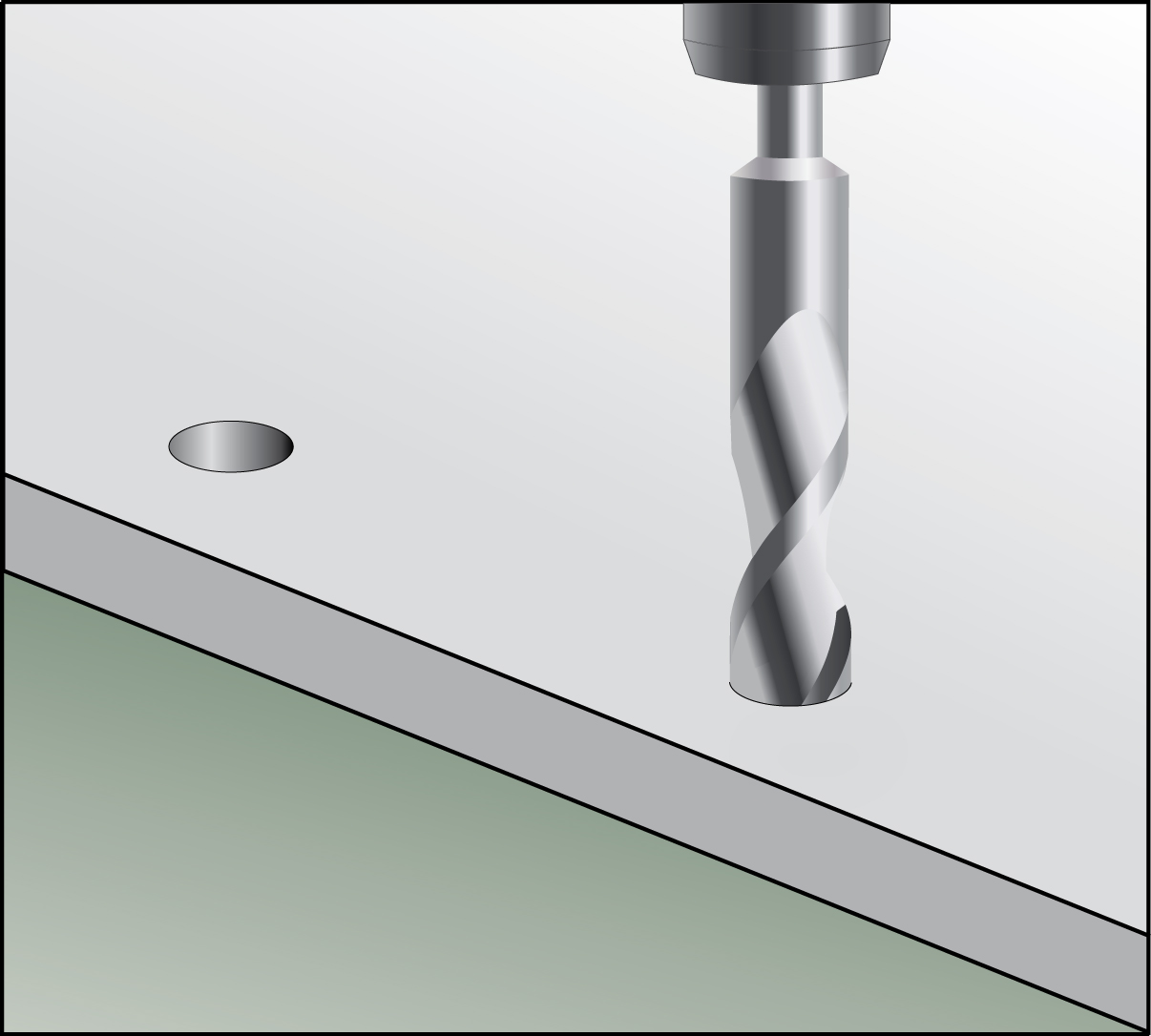

Drilling

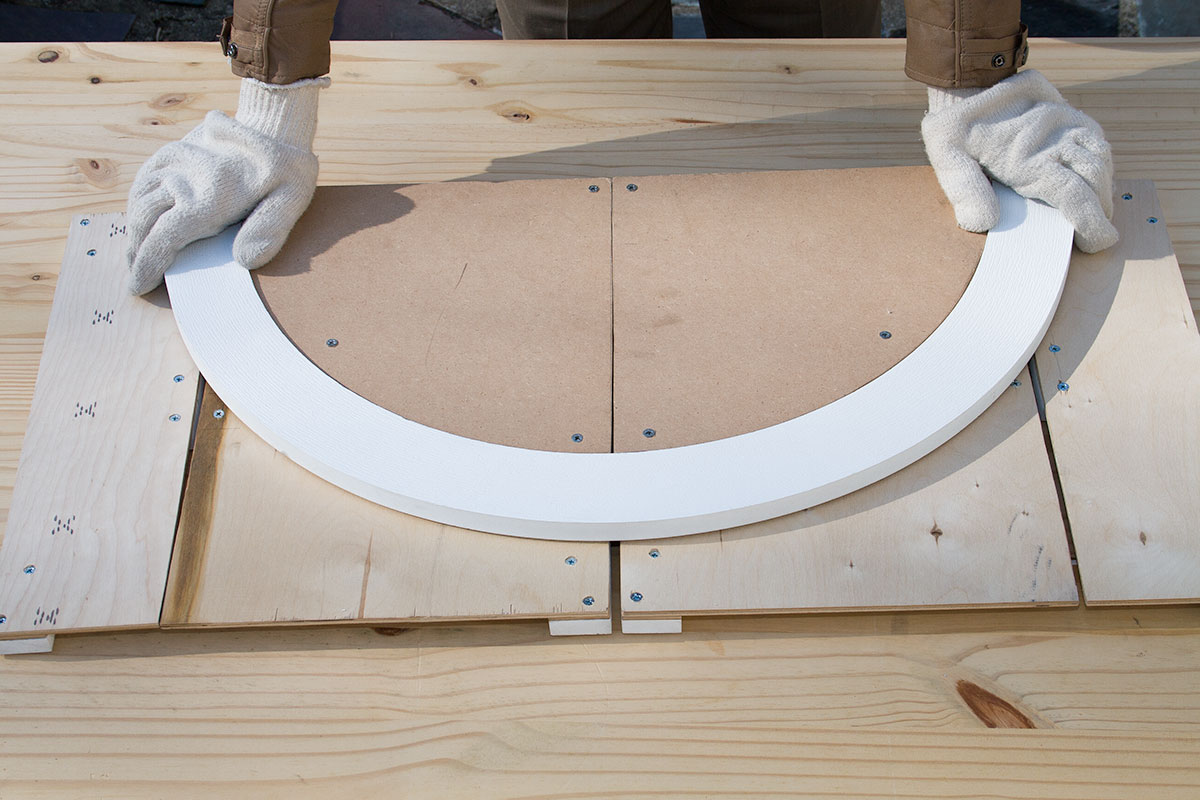

Bendability

No other traditional building materials can give you the creativity in architectural style and detail as Inteplast when it comes to finishing touches of a house. With our trim and millwork products, you can create custom shapes and curves through an advanced heat-bending process for unlimited craftsman applications.

In addition, our embossing technology keeps the wood grain patterns intact during the heat bending process so you can maintain the authentic-looking wood texture while creating custom shapes and curves for unlimited craftsman applications.