Preparation

1. Always wear proper protective clothing, safety glasses, and safety equipment, as well as adhere to all safety guidelines contained herein.

2. Like wood, minor color variation of Inteplast Deck and Décor Deck will occur.

3. Make sure all joists are leveled, structurally sound, and no nails or screws are protruding if facilitated by using old joist structure.

4. For appropriate joist spacing:

a) Do not exceed 16” on center for applications with deck boards perpendicular to joists

b) Do not exceed 12” on center for commercial applications.

c) Do not exceed 12” on center for diagonal or a Herringbone-pattern structure.

d) Do not exceed 11” on center for stair tread applications.

5. Temperature build-up will cause excessive expansion and contraction. There must be a minimum of 12” between the substructure and ground surface to allow proper air-flow and reduce temperature build-up underneath the deck.

Cutting

1. Use standard wood working equipment for cutting.

2. Carbide tipped blade is recommended.

3. Avoid using fine tooth metal cutting blades.

4. Rough and chipped edges from cutting may be caused by dull saw teeth, excessive friction, poor board support, or improper tooling.

Hidden Fastener

1. Inteplast Building Products can be installed by hidden fasteners. This choice provides a more attractive surface.

2. Please contact the manufacturer of the fastener for proper use and compatibility.

Spacing

1. Use spacers to create a gap of 1/8” to 1/4” between each deck board to allow for proper drainage. Spacers are available at most lumberyards.

2. Optional spacer: Edge of a carpenter’s square.

Expansion & Contraction

1. Inteplast Building Products Deck is engineered for minimal expansion and contraction with changes in temperature. Fasten Inteplast Building Products Deck according to the Installation Guidelines to minimize expansion and contraction.

2. Best practice is to fasten Inteplast Building Products Deck boards as soon as possible after being cut.

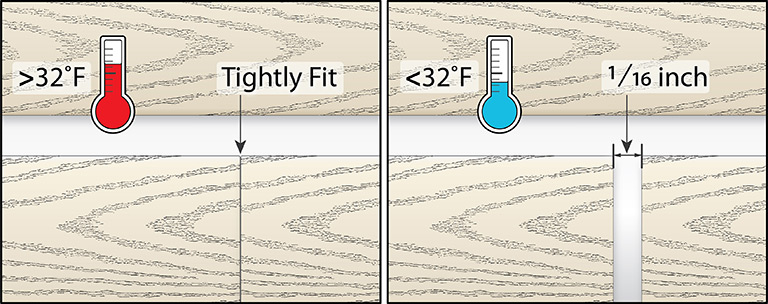

3. When deck surface temperature is above 32°F, fit deck boards tightly at the ends.

4. When deck surface temperature is 32°F or below, allow approximately an 1/16” to 1/8” end gap.

5. Deck boards fastened securely using 2 screws per joist member will minimize expansion and contraction.

6. Expansion & contraction are most significant when extreme

temperature change exist. Some area building codes require double joisting when joining boards end-to-end. Always check with your local code authority for specific requirements before installation.

7. On end-to-end splices, be sure the screws are placed within ½” of spliced end, Throughout the length of the board, screws should not exceed 1” from edge/side of the board. Additional screws on the end of boards are recommended to minimize its expansion and contraction.

8. No more than 1” overhang of the board from joist structure on the end and edge/side. Flushing with the joist structure is recommended to prevent deformation.

9. Fasten deck boards on top of the proper joist structure directly. Do not fasten the boards on top of the old deck boards.

Storage & Handling

1. Always store the products on a flat & level surface,and in the shade.

2. Do not store the product in any location where ambient temperature may exceed 120°F.

3. Do not stack bundles in an unsecured height.

4. Keep product free of dirt and debris at all times by leaving the applied factory wrap to protect the material. If product gets dirty, clean after installation.

5. Inteplast Building Products Deck is more flexible than wood. Do not try to lift similar quantities of Inteplast Building Products Deck as you would with traditional lumber.

6. Carry the Product with care to prevent excessive sagging and to minimize damage

7. Handle with care when moving products with a forklift, as forks can easily damage the boards.

8. If repacked with banding, use protective covers to prevent possible damage.

Other Factors To Consider

1. Low E Glass Considerations:

If Low E (Low Emissivity) glass windows or doors are used around the deck, its reflection of sunlight may create additional, excessive heat that could damage your Inteplast Building Products Deck. The damages may include but are not limited to melting, discoloration, excessive expansion and contraction or rapid weathering. A combination of contributing factors must be present before the effect occurs or causes damage to any nearby decking materials. This damaging effect can prevent in many cases by installing the window screens supplied by the window manufacturer.

2. Chemical Products:

Some products, including but not limited to sun-block and insect repellent, may contain chemicals or additives, that will alter the surface of Inteplast Building Products Deck. Please check product labels, consult the manufacturer, and/or contact us to ensure compatibility prior to use on or near Inteplast Building Products Deck.

3. Avoid the use of rubber or vinyl materials such as grill mats, rubber backed welcome mats, vinyl or PVC potted containers, etc. on the porch for an extended period of time. Additives in the rubber and PVC products have a tendency to migrate from these materials to Inteplast Building Products Deck, resulting in discoloration of the surface.