SPANNING

1.Inteplast Building Products must not be used in load bearing applications, but maybe used in spanned applications such as soffit and ceiling, with suitable thickness and support.

2.Do not span Inteplast Building Products TRIM exceeding 16” without following instructions below: in case of spanning Inteplast Building Products Trim 16”-24”, use Inteplast Building Products TRIM with 1” in thickness. Inteplast Building Products Trim should never span more than 24”

3. Inteplast Building Products Beadboard spanning consideration:

a) Run boards perpendicular to structure when possible to create shortest run of material.

b) When using 1/2” beadboard, use 12”o.c. framing and apply a high quality construction grade polyurethane adhesive on the joists. For spans over 12” o.c., use a minimum 1/2” backer such as plywood or OSB.

c) When using 5/8” beadboard, use 16”o.c. framing and apply a high quality construction grade polyurethane adhesive on the joists. For spans over 16” o.c., use a minimum 1/2” backer such as plywood or OSB.

EXPANSION & CONTRACTION

1.Inteplast Building Products Trim expand and contract with change in temperature. Allow 1/8” space per 18 feet at ends for expansion and contraction.

2. Joints between pieces should be glued to eliminate joint separation—see “gluing” section.

3. Properly fastening Inteplast Building Products Trim along its entire length will minimize expansion and contraction.

4. When gaps are glued on long runs, allow suitable expansion and contraction space at ends of the run.

5. Glued scarf joints are recommended to minimize seams and allow expansion & contraction at ends of the boards.

DRILLING AND ROUTING

1. Use standard wood working drills and routers.

2. Care should be taken to avoid frictional heat build-up.

3.periodic removal of shaving from the drill hole may be necessary.

4. Carbide tipped router bits recommended.

MOISTURE

1. Inteplast Building Products Trim products do not absorb moisture and can be installed at or below grade.

2. It is perfect for use in moisture prone applications such as ground contact, masonry contact, hot tub surrounds, frieze boards, and garage door jambs, etc.

STORAGE AND HANDLING

1. Store on a flat and level surface.

2. Should be handled similar to pine, as it has a density comparable to pine, but more flexible.

3. Keep product free of dirt and debris at job site. If product gets dirty, use warm water with detergent or soap to clean after installation.

TOUCH UP

1. Recommend non-solvent base fillers such as All Purpose Painter’s Putty, High Performance Wood Filler, Plastic Wood, etc.

2. Clean with a damp cloth using soap and water.

FASTENING

1.Stainless steel or hot-dipped galvanized nails are recommended. Use fasteners designed for wood trim. An 8d round-head nail or #8 trim screw may be used and works well with Inteplast Building Products Trim.

2. Do not use brads, staples, wire nails, ring-shank nails or fine-threaded wood screws.

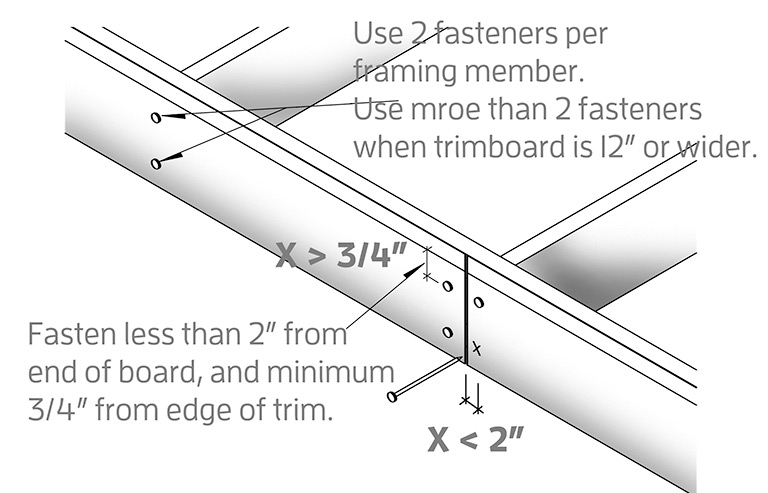

3. Use two fasteners per framing member for trim board applications. Inteplast Building Products Trim of 12” or wider will require additional fasteners, not to exceed 8” o.c.

4. Place nails and screws approximately 3/4” from the edges and within 2” of the end of Inteplast Building Products Trim

5. Fasteners should penetrate into flat, solid wood substrate or framing member a minimum of 1-3/8”.

6. When fastening Inteplast Building Products Trim at 32°F or below, pre-drilling is required.

7. Pre-drilling and/or counter-sinking are typically not required unless a larger fastener is used.

8. Handle with care when moving products with a forklift, as forks can easily damage the boards.

9. If repacked with banding, use protective covers to prevent possible damage.

CUTTING

1. Use standard wood working equipment for cutting.

2. Carbide tipped blades are recommended.

3. Avoid using fine tooth metal cutting blades.

PAINTING

Inteplast Building Products Trim does not require painting for protection. If painting is preferred:

1. Clean surface prior to painting.

2. Acrylic or urethane based latex exterior or interior paints are recommended. Follow the paint manufacturer’s recommendations for use and compatibility. General brands such as Sherwin Williams, Glide, etc. are all suitable.

3. Avoid painting dark colors. In case of painting darker colors (LRV of 54 or lower), use vinyl-safe paints specially custom made or mixed for vinyl products.

GLUING

1. Standard PVC cements or Cellular PVC cements provide a strong Inteplast Building Products to Inteplast Building Products bond.

2. For best results, glued scarf joint is required, failure to do so may result in joint separation. Glue all Inteplast Building Products to Inteplast Building Products joints such as long fascia runs, window surrounds, etc., to prevent joint separation.

3. Various adhesives, such as epoxy or polyurethane adhesives may be used to bond Inteplast Building Products to other substrates. Consult adhesive labeling to determine suitability.

4. The glued joints should be secured with fasteners on each side of the joint.